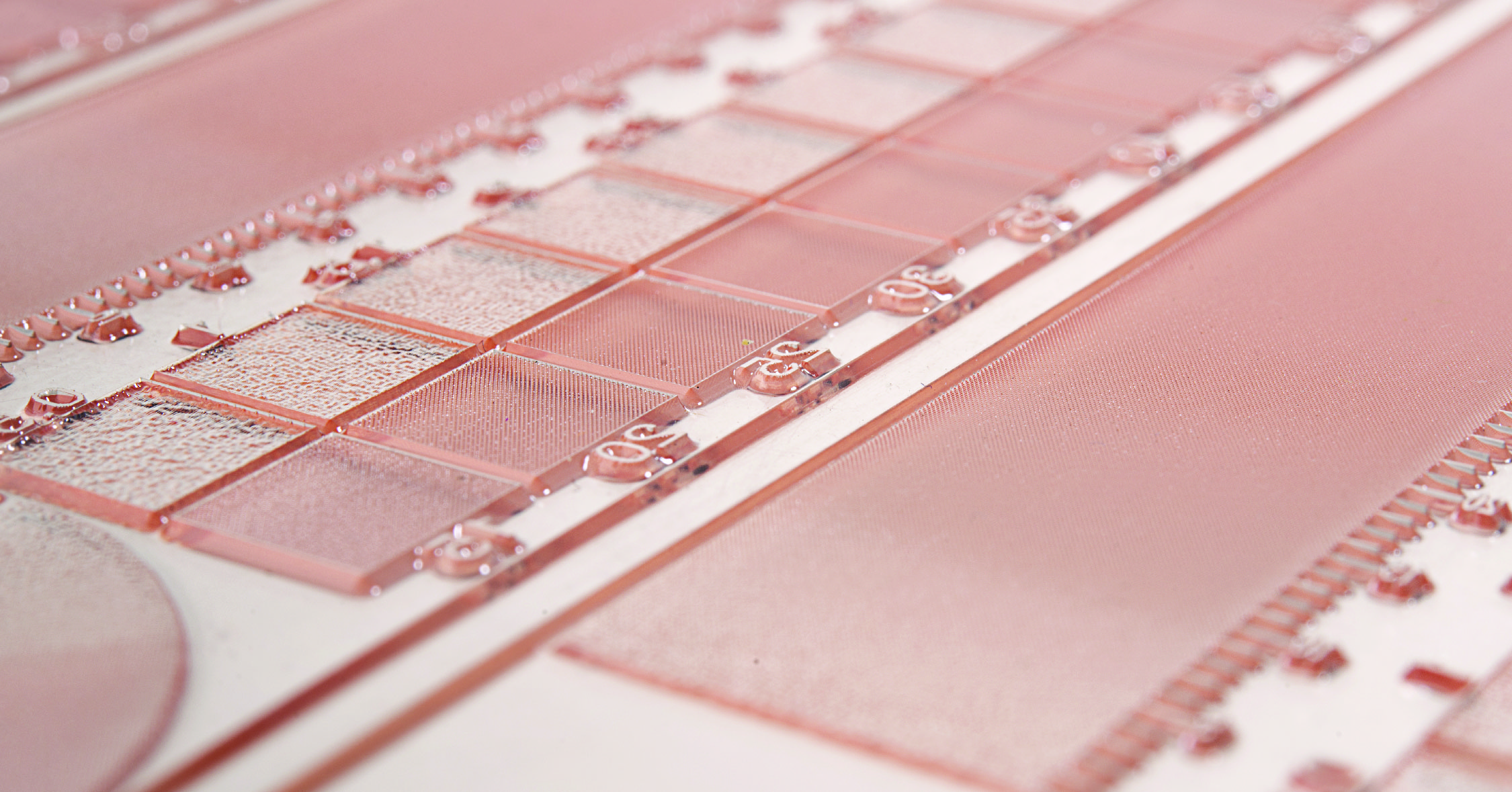

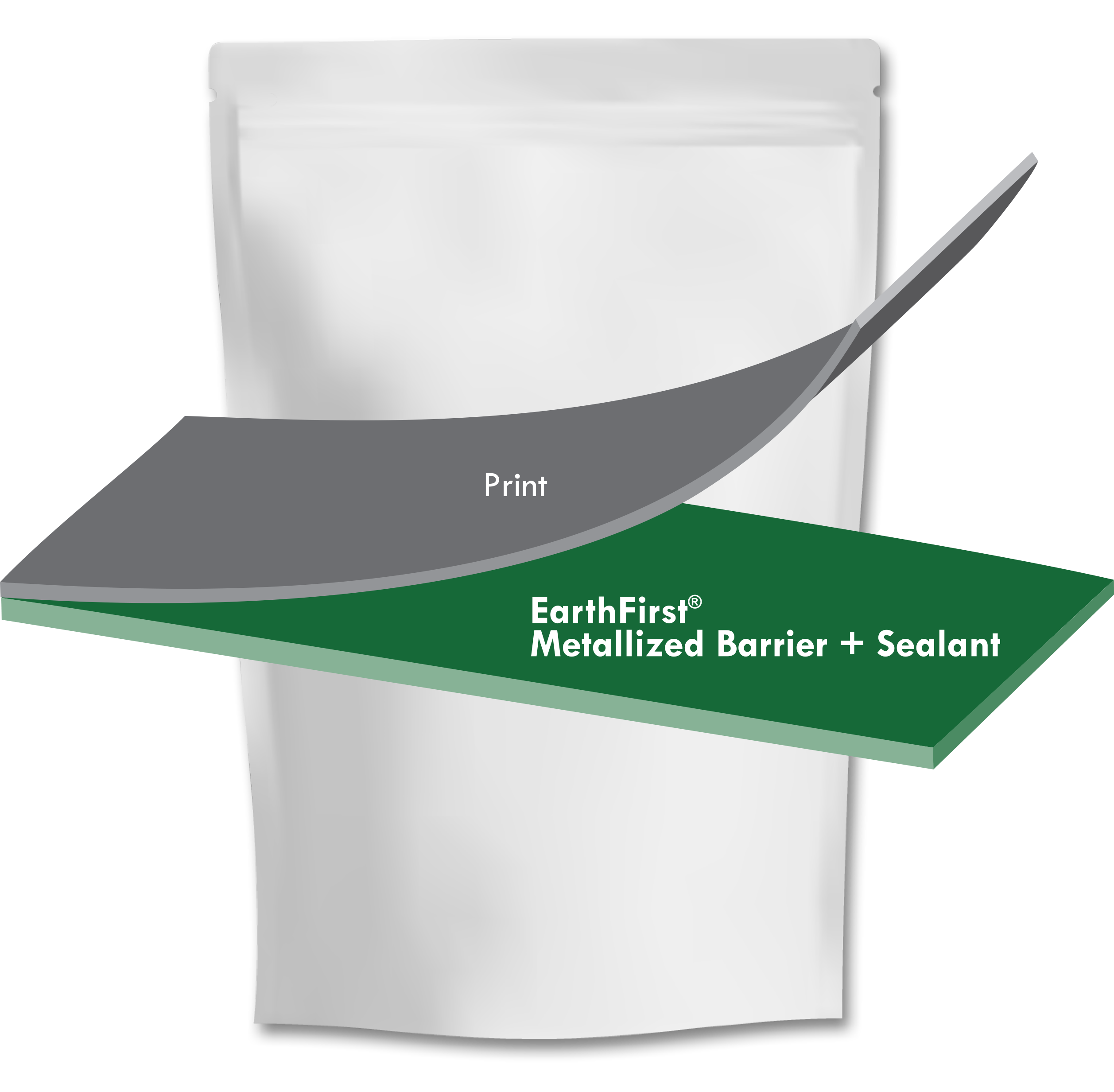

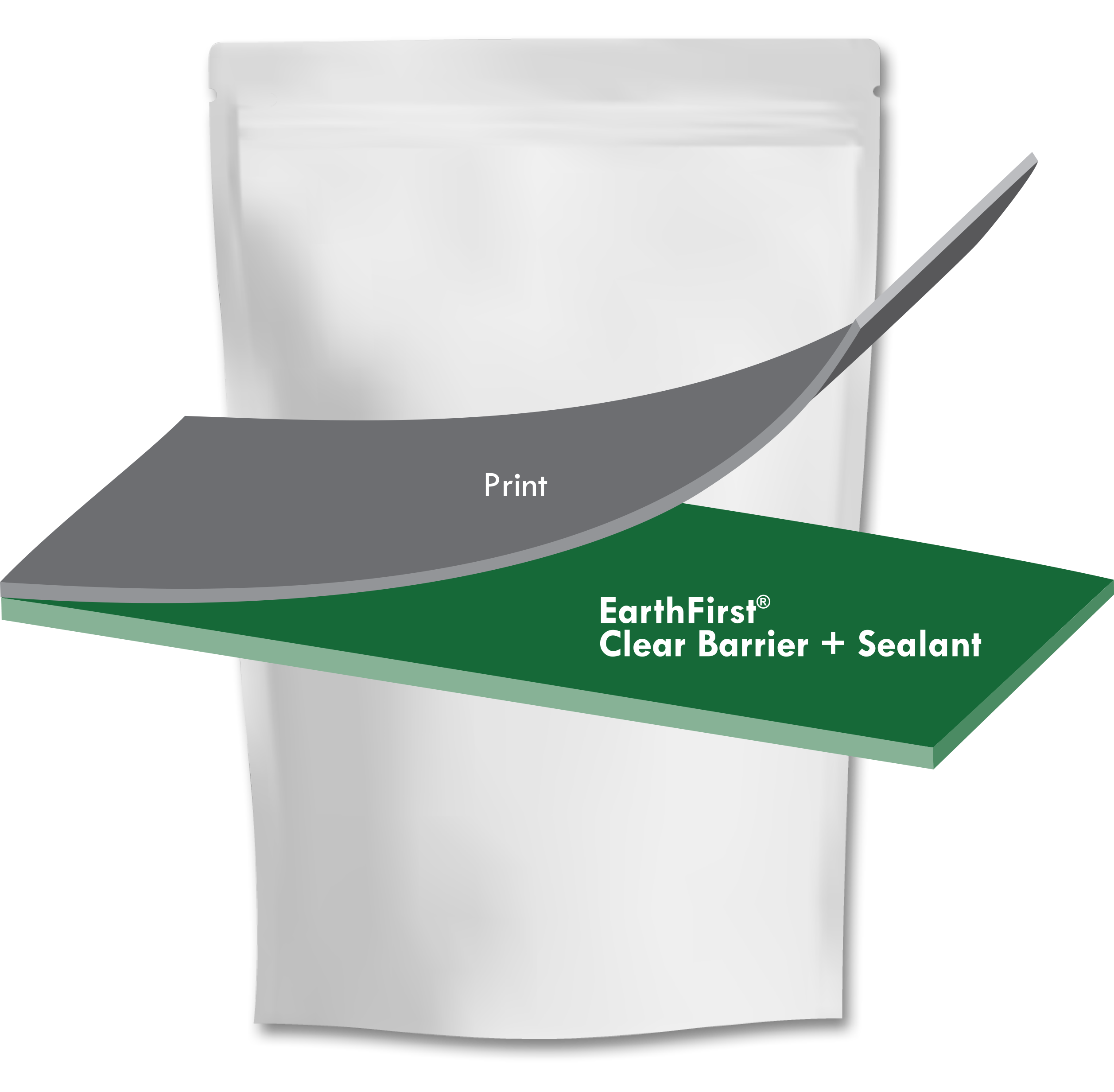

In our first episode of Sustainability Snacks, we welcomed Chris Schaefer from Plastic Suppliers, Inc. PSI is a member of our VIA ReSolve Sustainable Packaging Program which aims to help brands achieve 100% reusable, recyclable, or compostable packaging. In this program, PSI showcases their EarthFirst® line of Bioplastic PLA films. This natural Bioplastic is made from lactic acid found in sugars and starches.

“As brands establish stronger sustainability objectives, they are seeking to connect natural and organic products to more eco-friendly packaging,” explains Schaefer. “PLA films have the ability to significantly reduce the carbon footprint of a package while providing cost savings.” In addition to reducing the carbon footprint, PLA films can reflect both an improved origin of life and a more positive end of life for various packaging formats. These advantages make PLA films the perfect solution to the sustainability goals of many companies.

PSI is helping to revolutionize the way that greenhouse gas and fossil fuel reductions are measured and communicated to their clientele. They can calculate concrete environmental benefits such as the amount of tree seedlings grown or barrels of oil saved from a transition to thinner packaging. By transforming data into understandable facts and figures, it becomes more impactful to consumers who are interacting with the products on a day-to-day basis.

One especially beneficial feature of Bioplastic PLA film is its biodegradability in soil and marine environments. However, as Schaefer explains, this does not mean that the product should end up in nature or bodies of water. “PSI certainly does not condone littering, but rather provides a safety net for any accidental or unintentional littering that may occur.”

Currently, PSI is working on the next evolution of compostable films, specifically those that include home, soil, and marine compostability. These films require specialty resins and additives to be combined with the PLA films, and are expected to be developed between 2021-2022.

In her closing remarks Schaefer mentions, “Any incremental step towards sustainability is a positive one.” Although some packages will inherently end as solid waste in a landfill, they are ending as less waste because the Bioplastic PLA film is incredibly thin and the materials have an annually renewable source. PSI is taking initiative to provide brands with materials that simultaneously meet their sustainability goals and packaging needs, protecting our planet for future generations to come.

For more information on PSI’s Bioplastic PLA film, visit their website here.